Sand Castings Excellence

Our expertise in sand casting extends to a wide spectrum of order quantities, shapes, and sizes. While our production line capably handles up to 150kg of finished weight, our foundry boasts the capacity to accommodate larger castings through offline processes. For enquiries about these capabilities, please get in touch with a member of our dedicated sales team.

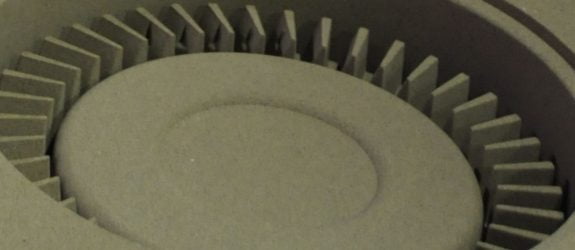

Sand Mould Design

Creating precision sand moulds is at the heart of our sand casting process. Utilising wood, metal, or plastic patterns, we blend sand with a binder and hardener in high-speed mixers. This mixture is then meticulously poured into moulds housing the patterns. Within minutes, the sand solidifies, allowing us to detach the mould from the pattern. Moreover, our skilled team can produce cores to establish internal passages within the casting. Once these processes are complete, the moulds are sealed and prepared for the crucial metal pouring stage.

Pattern Design Expertise

At Precision Aluminium Casting & Engineering, we work closely with our customers and expert partners to ensure seamless pattern design. Whether utilising 3D CAD models or converting 2D drawings, our aim is to create patterns optimised for manufacturing. Additionally, we offer Finite Element Analysis, a valuable tool that models material flow within the casting, identifying and addressing potential issues prior to pattern production.

Sustainability at the Core

Our sand casting process embodies efficiency and sustainability. Notably, we employ a fully computerised reclaim system to recover and reintroduce sand into the production cycle, minimising waste. We take pride in pioneering environmental responsibility, having been the first foundry worldwide to adopt a low-odour urethane system for our sand moulds. This eco-conscious choice aligns with the best available technology, ensuring the highest environmental performance while maintaining our commitment to excellence.